400-816-6687

400-816-6687ZHWR-64A Temperature Control Device Intelligent Test System (30 Stations)

I. Overview

Thermostat Temperature Test Bench (hereinafter referred to as the test bench):

This equipment, in accordance with GB14536.1-2008, is primarily used to measure the operating

and reset temperatures of thermostats. The test bench can simultaneously test up to 40 thermostats,

record the values, automatically determine the pass/fail status of the test results, and calculate statistical values.

All statistical results can be stored for future verification.

The test bench consists of three parts: the housing, the electrical box, and the computer.

The housing is located to the left of the electrical box and has a circular structure.

A blower distributes heat generated by the heater evenly and rapidly from the furnace bottom to the furnace top,

heating the workpiece under test placed in the furnace fixture. A valve is located below the furnace.

When the furnace temperature needs to be lowered rapidly, it is automatically opened pneumatically to

allow low-temperature air to cool the furnace.

The electrical box uses a programmable controller (PLC) to sample the thermostat's on/off status.

The computer collects this information through the PLC and processes it.

A high-precision thermometer on the panel displays and controls the furnace temperature,

transmits this information to the computer, and receives control commands from the computer.

The computer consists of a host computer, monitor, keyboard, printer, and 485A/232A converter.

It receives operator commands and communicates with the relevant components of the electrical box,

continuously collecting temperature and switching information, and executing the corresponding components

according to the program. After the test is complete, the results are printed.

The test program runs on the Windows operating system. The operator enters the required data,

and the computer automatically enters the corresponding program. After the test is completed,

if you need to print the test results, you can enter the corresponding command, and the printer will print the results.

II. Main Technical Specifications and Operating Conditions:

1. Key Technical Specifications:

· Test Range: Room Temperature to 220°C

· Medium: Air

· Uniformity: ≤±0.8°C (Testing area on the same plane, below 200°C, uniformity ±1.5°C between 200°C and 220°C)

· Temperature Control Zone Speed: 0.5°C to 3°C/min

· Temperature Controller: Accuracy 0.2%, Resolution 0.1°C

· Test Quantity: 30 snap-action thermostats can be tested, only one product can be tested at a time

· Fixture: Each chamber is equipped with a fixed fixture plate. The fixed fixture plate has 30 stations,

suitable for several products currently provided by the client, and can test up to 30 thermostats.

The fixture uses spring clips for quick connection, suitable for connecting to a variety of terminals.

Please contact the manufacturer for orders with replaceable fixture plates.

· Automatic measurement mode. Continuous operation is recommended for no more than 16 hours.

Power consumption is less than 4 kW.

Each station has an indicator on the computer displaying its on/off status.

Automatic data recording (recording the time of abnormal disconnection)

Control temperature and time are set by the computer.

The fixture uses high-temperature-resistant insulators to prevent deformation at high temperatures,

which could affect testing.

The fixture uses a clamping method for sampling, ensuring versatility in workpiece testing and suitable for

testing various thermostats.

Low-voltage sampling is applied to the sample terminals, ensuring that even samples containing

heating elements will not affect testing.

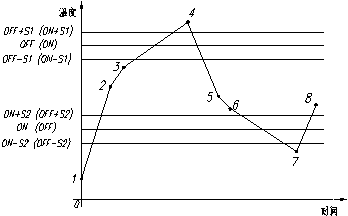

2. Working curve

Note: 1-2 is the rapid heating phase, with a heating rate > 3°C/minute;

2-3 is the pre-heating phase, where the heating rate is controlled before entering the test zone;

3-4 is the constant heating phase, with an adjustable heating rate of 0.5-1°C/minute;

4-5 is the rapid cooling phase, with a cooling rate > 3°C/minute;

5-6 is the pre-cooling phase, where the cooling rate is controlled before entering the test zone;

6-7 is the constant cooling phase, with an adjustable cooling rate of 0.5-1°C/minute.

During the test, the operator simply sets the upper and lower operating

temperature limits (points 3 and 4 in the figure) and the upper and lower reset

temperature limits (points 6 and 7 in the figure). The system automatically completes the heating

and cooling process and displays the operating and reset temperatures on the human-machine interface.

ZHWR-64A Temperature Control Device Intelligent Test System (30 Stations)

I. Overview

Thermostat Temperature Test Bench (hereinafter referred to as the test bench):

This equipment, in accordance with GB14536.1-2008, is primarily used to measure the operating

and reset temperatures of thermostats. The test bench can simultaneously test up to 40 thermostats,

record the values, automatically determine the pass/fail status of the test results, and calculate statistical values.

All statistical results can be stored for future verification.

The test bench consists of three parts: the housing, the electrical box, and the computer.

The housing is located to the left of the electrical box and has a circular structure.

A blower distributes heat generated by the heater evenly and rapidly from the furnace bottom to the furnace top,

heating the workpiece under test placed in the furnace fixture. A valve is located below the furnace.

When the furnace temperature needs to be lowered rapidly, it is automatically opened pneumatically to

allow low-temperature air to cool the furnace.

The electrical box uses a programmable controller (PLC) to sample the thermostat's on/off status.

The computer collects this information through the PLC and processes it.

A high-precision thermometer on the panel displays and controls the furnace temperature,

transmits this information to the computer, and receives control commands from the computer.

The computer consists of a host computer, monitor, keyboard, printer, and 485A/232A converter.

It receives operator commands and communicates with the relevant components of the electrical box,

continuously collecting temperature and switching information, and executing the corresponding components

according to the program. After the test is complete, the results are printed.

The test program runs on the Windows operating system. The operator enters the required data,

and the computer automatically enters the corresponding program. After the test is completed,

if you need to print the test results, you can enter the corresponding command, and the printer will print the results.

II. Main Technical Specifications and Operating Conditions:

1. Key Technical Specifications:

· Test Range: Room Temperature to 220°C

· Medium: Air

· Uniformity: ≤±0.8°C (Testing area on the same plane, below 200°C, uniformity ±1.5°C between 200°C and 220°C)

· Temperature Control Zone Speed: 0.5°C to 3°C/min

· Temperature Controller: Accuracy 0.2%, Resolution 0.1°C

· Test Quantity: 30 snap-action thermostats can be tested, only one product can be tested at a time

· Fixture: Each chamber is equipped with a fixed fixture plate. The fixed fixture plate has 30 stations,

suitable for several products currently provided by the client, and can test up to 30 thermostats.

The fixture uses spring clips for quick connection, suitable for connecting to a variety of terminals.

Please contact the manufacturer for orders with replaceable fixture plates.

· Automatic measurement mode. Continuous operation is recommended for no more than 16 hours.

Power consumption is less than 4 kW.

Each station has an indicator on the computer displaying its on/off status.

Automatic data recording (recording the time of abnormal disconnection)

Control temperature and time are set by the computer.

The fixture uses high-temperature-resistant insulators to prevent deformation at high temperatures,

which could affect testing.

The fixture uses a clamping method for sampling, ensuring versatility in workpiece testing and suitable for

testing various thermostats.

Low-voltage sampling is applied to the sample terminals, ensuring that even samples containing

heating elements will not affect testing.

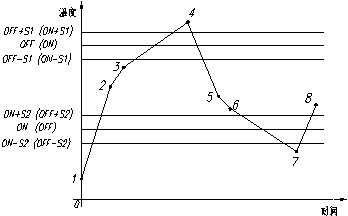

2. Working curve

Note: 1-2 is the rapid heating phase, with a heating rate > 3°C/minute;

2-3 is the pre-heating phase, where the heating rate is controlled before entering the test zone;

3-4 is the constant heating phase, with an adjustable heating rate of 0.5-1°C/minute;

4-5 is the rapid cooling phase, with a cooling rate > 3°C/minute;

5-6 is the pre-cooling phase, where the cooling rate is controlled before entering the test zone;

6-7 is the constant cooling phase, with an adjustable cooling rate of 0.5-1°C/minute.

During the test, the operator simply sets the upper and lower operating

temperature limits (points 3 and 4 in the figure) and the upper and lower reset

temperature limits (points 6 and 7 in the figure). The system automatically completes the heating

and cooling process and displays the operating and reset temperatures on the human-machine interface.

Zhipinhui After-Sales Policy:

*After-Sales Hotline: +864008166687

1. Our company has assembled a team of experienced field engineers and senior technicians to promptly respond

to any equipment issues and provide after-sales maintenance.

2. Within China, within one week of new product delivery, our after-sales technical staff will install the equipment and

provide after-sales training at the customer's location, using the contact information and address provided by the customer.

3. All complaints related to product quality will be responded to within one hour. Within 3-5 hours within the province,

and within 24-48 hours outside the province, we will arrive at the customer's site,

determine the appropriate action based on the complaint, and provide after-sales repairs. (Domestic)

4. For international travel, our company can also arrange for an after-sales engineer to visit you for installation and

commissioning. Please discuss any travel and catering issues in advance.

We also provide video installation guides for you to choose from, providing you with a comprehensive and multi-faceted solution.

5. Any material costs related to product quality during the warranty period will be borne by our company.

6. During the warranty period, we will provide free repairs due to improper use or environmental factors.

The materials and accessories used for repairs will be charged at cost only.