400-816-6687

400-816-6687

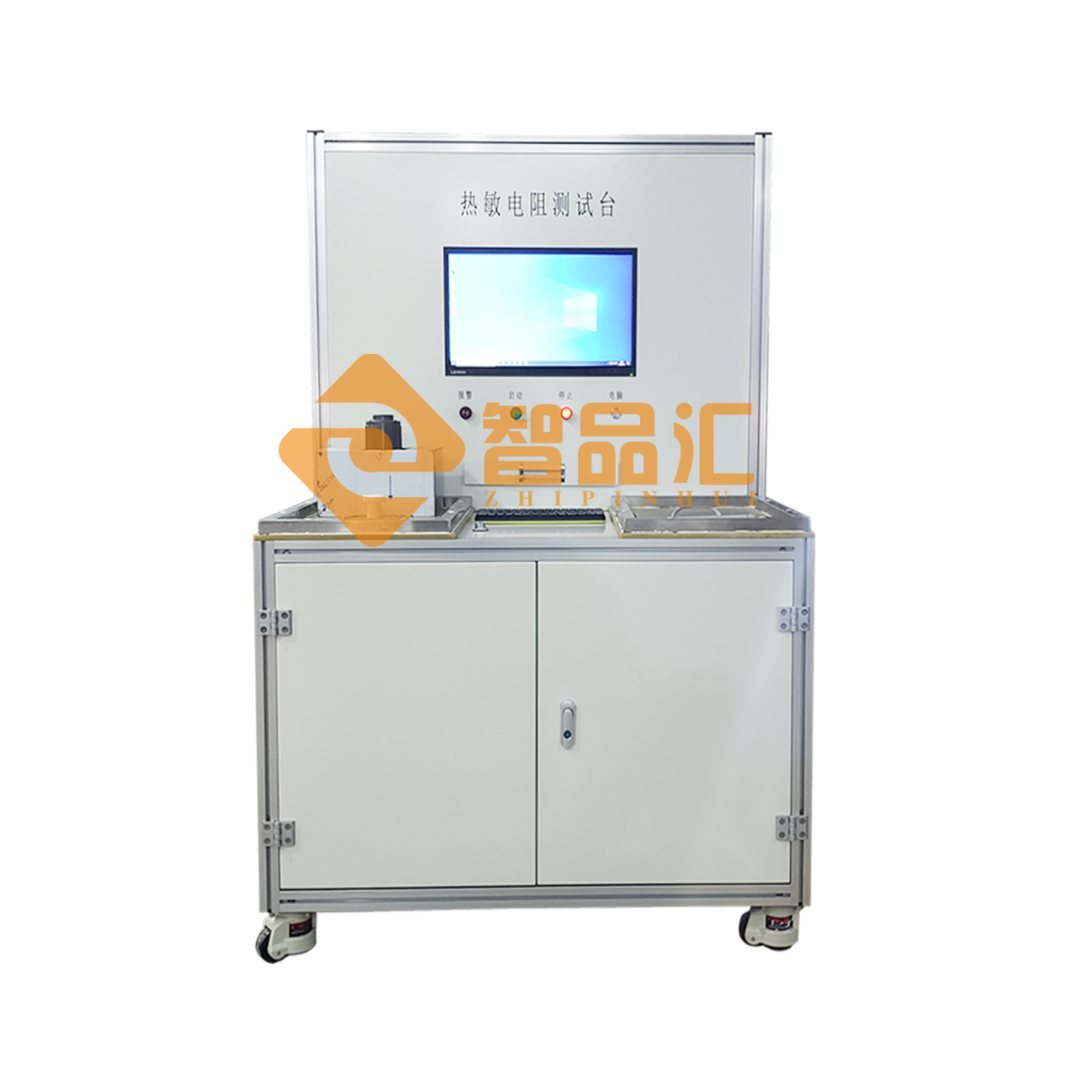

Device Usage: It is suitable for testing the temperature characteristics and resistance values of thermistors of various specifications. | ||

Working positions: 10 working stations | ||

Specific parameters and requirements | Basic functional requirements | 1. Power supply: 220V, 50Hz, with a power less than 2000W. |

2. Temperature range: Room temperature + 5°C to 100°C | ||

3. Temperature control accuracy: ±0.2%. | ||

4、The temperature uniformity is ≤ 0.2℃. | ||

5、The measurement range of the resistance value is 0 - 20KΩ, with an accuracy of 1Ω. | ||

6、The tooling is suitable for installing thermistors of various series. The resistance under test is connected to the device through terminal blocks. Each port has a 6-millimeter through hole inserted into the silicone oil. | ||

7、Cooling method: Compressed air cooling (optional) | ||

8、Medium: High-temperature silicone oil (0-200℃). The test machine includes the rated usage amount of silicone oil. Additionally, one more portion of silicone oil with the same specifications and quantity should be prepared as a backup. The silicone oil is an insulating medium, which is suitable for accurately testing the resistance value. | ||

9、Heating and temperature control method: The heating tube generates heat, and the motor stirring device stirs to make the temperature of the entire temperature tank uniform. The high-precision temperature controller senses the temperature through a four-wire PT100 sensor, and the PID output controls the heating power to achieve temperature control. The minimum rate of temperature rise and fall is less than 0.5°C per minute. | ||

10、Specifications of the medium installed in the box body: The volume is approximately 10 liters, and the opening diameter is no larger than φ160. | ||

11、Working environment: 5-45℃ / 25%-85%RH | ||

Software Requirements | 1、Testing software: The heating rate is 0.5°C per minute. The software automatically records the resistance values of each working station after reaching the set temperature (the current temperature and the corresponding resistance value). The resistance values are scanned. A precision resistance tester is configured. After reaching the temperature, the system automatically scans the resistance values of each working station and records them in the software. The scanning frequency is less than 2 seconds. The software can automatically generate reports or draw temperature-resistance curve graphs. | |

2、It supports the setting of multiple temperature points and can automatically complete the operation (for example: 30°C - 35°C - 40°C - 45°C - 50°C - 55°C - 60°C). | ||

3、It can be set for automatic heating-up testing and manual testing. | ||

4、The device has a fault alarm function. Different indicator lights will turn on after the test is completed. | ||

5、The device is equipped with safety devices for leakage point protection and under-voltage protection. | ||

6、The software supports the function of automatically saving data. | ||

7、Data in the report format can be exported. | ||

8、The computer configuration should have a processor of Intel Core i3 or higher, a hard disk of 500GB or larger, and use the Windows 7 operating system. | ||

Zhipinhui After-Sales Policy:

*After-Sales Hotline: +864008166687

1. Our company has assembled a team of experienced field engineers and senior technicians to promptly respond

to any equipment issues and provide after-sales maintenance.

2. Within China, within one week of new product delivery, our after-sales technical staff will install the equipment and

provide after-sales training at the customer's location, using the contact information and address provided by the customer.

3. All complaints related to product quality will be responded to within one hour. Within 3-5 hours within the province,

and within 24-48 hours outside the province, we will arrive at the customer's site,

determine the appropriate action based on the complaint, and provide after-sales repairs. (Domestic)

4. For international travel, our company can also arrange for an after-sales engineer to visit you for installation and

commissioning. Please discuss any travel and catering issues in advance.

We also provide video installation guides for you to choose from, providing you with a comprehensive and multi-faceted solution.

5. Any material costs related to product quality during the warranty period will be borne by our company.

6. During the warranty period, we will provide free repairs due to improper use or environmental factors.

The materials and accessories used for repairs will be charged at cost only.