400-816-6687

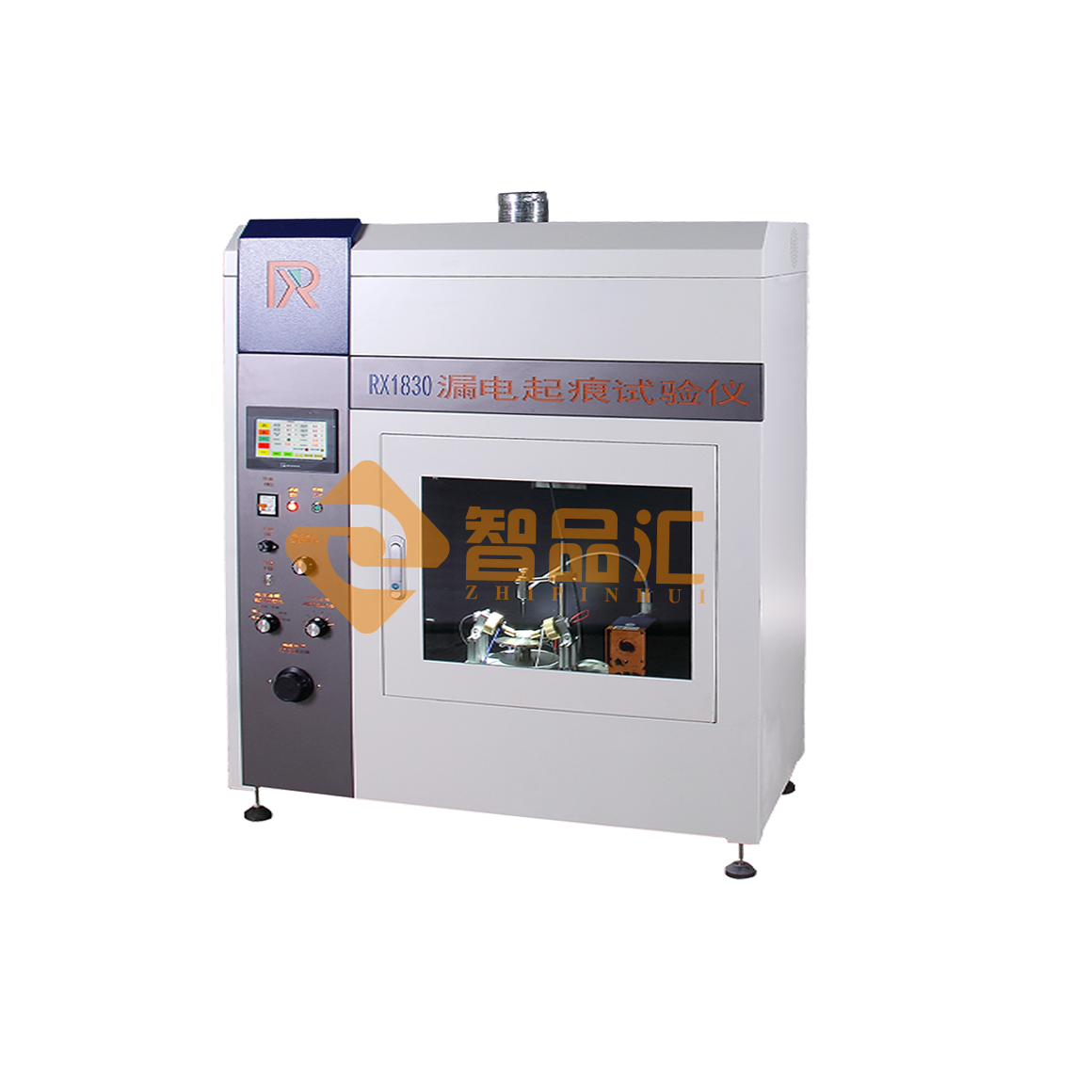

400-816-6687RX1830漏电起痕试验仪

漏电起痕试验仪是全不锈钢板加高档喷涂外箱;采用目前三菱PLC的嵌入式计算机控制,做到全智能化控制方式,真正实现网络化及远程控制;有5.7″(4:3),6.4″(4:3),7.0″(16:9)TFT真彩色液晶可选配;可做到客户的人性化操作界面的升级,真正达到国际比对结果。

漏电起痕试验仪是依据GB 4706.1、GB 4207、GB/T6553、GB7000.1、IEC60112 《固体绝缘材料耐电痕化指数和相比电痕化指数的测定方法》、 UL 746A 、 ASTM D 3638-92 、 DIN 53480等标准规定的仿真试验项目。

漏电起痕试验(电痕化指数试验)是在固体绝缘材料表面上,在规定尺寸 ( 2mm × 5mm ) 的铂电极之间,施加某一电压并定时 (30s) 定高度 ( 35mm ) 滴下规定液滴体积的导电液体 (0.1%NH 4 CL) ,用以评价固体绝缘材料表面在电场和潮湿或污染介质联合作用下的耐漏电性能,测定其相比电痕化指数 (CT1) 和耐电痕化指数 (PT1) 。

漏电起痕试验仪适用于照明设备、低压电器、家用电器、机床电器、电机、电动工具、电子仪器、电工仪表、信息技术设备的研究、生产和质检部门,也适用于绝缘材料、工程塑料、电气连接件、辅件行业。

性能参数:

控制方式 | 采用先进的三菱PLC计算机控制,做到全智能化控制方式 |

显示方式 | 真彩色液晶显示,可做到客户的人性化操作界面的升级 |

电极尺寸 | ( 2mm ± 0.1mm )×( 5mm ± 0.1mm )×( 40mm ± 5mm ) ,30°±2° 箔金部分长度:12mm (选配5mm) |

电极距离 | 4.0mm ± 0.01mm ,夹角 60°±5°; |

电极压力 | 1.00N±0.001N; |

称重系统 | 自带重量传感器(自动显示力值) |

试液电阻 | A 液 0.1%NH4Cl,3.95±0.05Ωm, B 液 1.98±0.05Ωm; |

液滴控制 | 德国进口微量泵 |

液滴体积 | 20 滴 0.380g ~ 0.480g , 50 滴 0.997g ~ 1.147g ( 可微调节 ); |

液滴高度 | 35mm ± 5mm ( 可调节 ); |

液滴时间 | 30s±0.1s( 优于标准 )( 数显,可预置调节 ) , 50 滴时间 24.5min±2min; |

液滴滴数 | 1 ~ 9999( 数显,可预置 ); |

试验风速 | 0.2m /s( 新标准 ); |

试验电压 | 100V ~600V(25V 分度,可调节 ); |

电源压降 | 1.0A ± 0.1A 时5%;(优于标准10%) |

电极材料 | 试验电极 - 铂金,电极接杆 – 紫铜或黄铜(选配纯银) |

排风系统 | 排风扇 \ 吹风扇(可调速度) 各一套 |

起痕判断 | 0.50A ±10% , 2.00s±10% ;报警声 |

外形尺寸 | 宽 1120mm × 深 520mm × 高 1350mm ,排气孔径Φ100mm; |

试验电源 | 220V 0.6kVA 50-60Hz 。 |

RX1830 Leakage Traceability Tester (New)

The tracking tester is a full stainless steel plate with a high-grade spray-coated outer box; it adopts the current Mitsubishi PLC embedded computer control to achieve full intelligent control mode, truly realizing networking and remote control; there are 5.7″ (4:3), 6.4″ (4:3), 7.0″ (16:9) TFT true color LCD optional; it can upgrade the customer's humanized operation interface and truly achieve international comparison results.

The tracking tester is a simulation test item specified in GB 4706.1, GB 4207, GB/T6553, GB7000.1, IEC60112 "Determination of Tracking Index and Comparative Tracking Index of Solid Insulating Materials", UL 746A, ASTM D 3638-92, DIN 53480 and other standards.

The tracking test (tracking index test) is a test on the surface of solid insulating materials at a specified size (2mm × 5mm ) between two platinum electrodes, a certain voltage is applied and a specified drop volume of conductive liquid (0.1% NH 4 CL) is dripped at a fixed height (35mm) at a fixed time (30s) to evaluate the leakage resistance of the surface of solid insulating materials under the combined action of electric field and humid or polluted media, and to determine its comparative tracking index (CT1) and tracking resistance index (PT1).

The leakage tracking tester is suitable for the research, production and quality inspection departments of lighting equipment, low-voltage electrical appliances, household appliances, machine tool electrical appliances, motors, power tools, electronic instruments, electrical instruments, and information technology equipment, and is also suitable for the insulation materials, engineering plastics, electrical connectors, and accessories industries.

Performance parameters:

Control method | Adopt advanced Mitsubishi PLC computer control to achieve fully intelligent control mode |

Display Mode | True color LCD display can upgrade the customer's humanized operation interface |

Electrode size | ( 2mm ± 0.1mm )×( 5mm ± 0.1mm )×( 40mm ± 5mm ) ,30°±2° Length of gold foil part: 12mm (optional 5mm) |

Electrode distance | 4.0mm ± 0.01mm ,Angle 60°±5°; |

Electrode pressure | 1.00N±0.001N; |

Weighing system | Built-in weight sensor (automatically displays force value) |

Test solution resistance | A liquid 0.1%NH4Cl,3.95±0.05Ωm, B liquid 1.98±0.05Ωm; |

Droplet control | Micro pump imported from Germany |

Droplet volume | 20 drops 0.380g ~ 0.480g, 50 drops 0.997g ~ 1.147g (finely adjustable); |

Droplet height | 35mm ± 5mm ( adjustable ); |

Drop time | 30s±0.1s (better than standard) (digital display, presettable), 50 drops time 24.5min±2min; |

Droplet count | 1 ~ 9999 (digital display, presettable); |

Test wind speed | 0.2m/s (new standard); |

Test voltage | 100V ~ 600V (25V division, adjustable); |

Power supply voltage drop | 5% at 1.0A ± 0.1A; (10% better than the standard) |

Electrode | Test electrode - platinum, electrode rod - copper or brass (optional sterling silver) |

Exhaust | Exhaust fan \ Blowing fan (adjustable speed) one set each |

Scar judgment | 0.50A ±10% , 2.00s±10% ;Alarm sound |

Dimensions | Width 1120mm × Depth 520mm × Height 1350mm, Exhaust hole diameter Φ100mm; |

Test power supply | 220V 0.6kVA 50-60Hz 。 |

Zhipinhui After-Sales Policy:

*After-Sales Hotline: +864008166687

1. Our company has assembled a team of experienced field engineers and senior technicians to promptly respond

to any equipment issues and provide after-sales maintenance.

2. Within China, within one week of new product delivery, our after-sales technical staff will install the equipment and

provide after-sales training at the customer's location, using the contact information and address provided by the customer.

3. All complaints related to product quality will be responded to within one hour. Within 3-5 hours within the province,

and within 24-48 hours outside the province, we will arrive at the customer's site,

determine the appropriate action based on the complaint, and provide after-sales repairs. (Domestic)

4. For international travel, our company can also arrange for an after-sales engineer to visit you for installation and

commissioning. Please discuss any travel and catering issues in advance.

We also provide video installation guides for you to choose from, providing you with a comprehensive and multi-faceted solution.

5. Any material costs related to product quality during the warranty period will be borne by our company.

6. During the warranty period, we will provide free repairs due to improper use or environmental factors.

The materials and accessories used for repairs will be charged at cost only.