400-816-6687

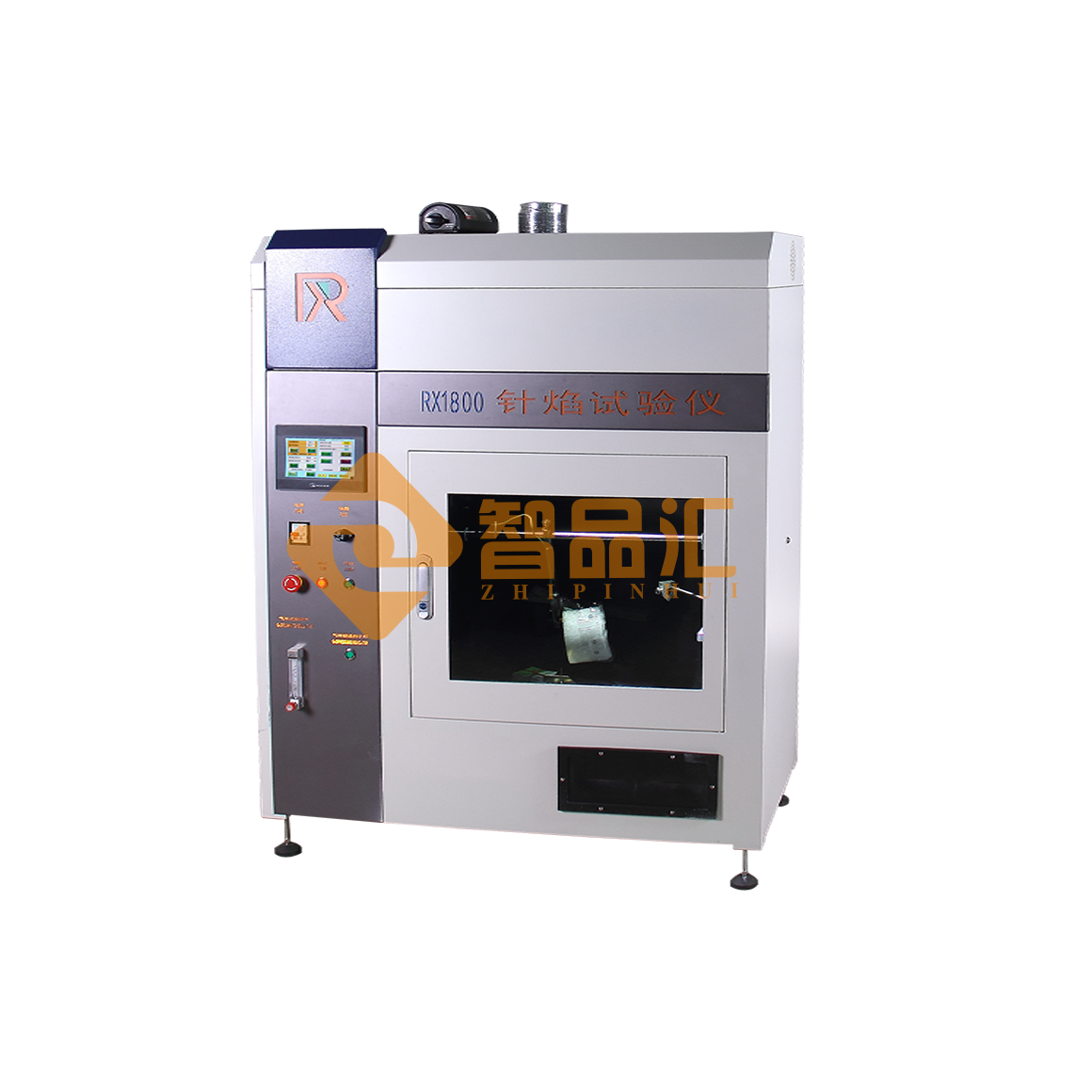

400-816-6687RX1800 Needle Flame Tester The needle flame tester is a simulated test item specified in standards such as IEC 60695-2-2, GB 5169, GB 4706, and GB 7000.1-2015. The needle flame tester features an outer box made of full stainless steel plate with high-grade spraying. It is controlled by a relatively advanced embedded computer, adopting an intelligent control mode, and truly achieving networked and remote control. It is equipped with a seven-inch TFT true-color liquid crystal touch screen from Weinview in Taiwan. It can upgrade the user-friendly operation interface for customers and truly achieve international comparison results. The needle flame tester uses a needle-shaped burner with a specified size (Φ0.9mm), supplies a specific gas (butane or propane), and applies the flame to the test sample at a 45° angle for a fixed time and in a fixed direction. The fire hazard of small flames caused by fault conditions inside the equipment is evaluated based on whether the test sample and the ignited backing layer are ignited, as well as the duration of sustained combustion and the length of combustion. The needle flame tester is applicable to the research, production, and quality inspection departments of electrical and electronic equipment and their components and assemblies, such as lighting, low-voltage electrical appliances, household appliances, machine tool electrical appliances, motors, electric tools, electronic instruments, electrical measuring instruments, information technology equipment, electrical office equipment, electrical connectors, and auxiliary components. It is also applicable to the industries of insulating materials, engineering plastics, or other solid combustible materials. Performance Parameters:

Control panel | Control interface: Chinese, Mitsubishi PLC + Weinview touch screen |

In line with the standards Compliant with the standards Meet the standards | IEC 60695-2-2 、GB 4706.1、GB 7000.1-2015In line with the standards Compliant with the standards Meet the standards |

Burner needle tube | A needle with a diameter of 0.5±0.1mm, an outer diameter not exceeding 0.9mm, and a length of more than 35mm, with no air supply. |

The material of the burner needle tube | Stainless steel |

Test angle | 90°、45°、20° |

Flame height | It is 12mm±1mm and can be adjusted according to the requirements of the standard. It is equipped with an adjustable flame height gauge, which is made of 304 material. |

Standard fixture | It can move up and down, left and right, and back and forth. |

Automatic positioning system | Use an infrared induction switch to automatically locate the position of the burner. |

Temperature display range | 0-9999℃, Resolution: 0.01℃ |

Gas regulation | It is equipped with the functions of gas flow and gas pressure adjustment. |

Temperature measurement system | b + b thermocouple (sheathed type K) + high-resolution copper head (Φ4mm±0.01mm, mass 0.58g±0.01g) |

Inside the test chamber | The illuminance meets the standard requirement, which is ≤20LX, making it convenient to observe the flame. |

Bedding material | Pine wood board (200*200*10mm), thin silk paper (1500*500mm) |

Gas source | 95% butane gas (reference gas), one standard bottle. |

Gas source location | Outside the test chamber (这里考虑到前面提到“试验箱体”,所以加上“test”,如果不是试验箱体,单纯的箱体就用“Outside the chamber” ) |

Temperature testing standard | 100~700℃ (When the temperature reaches 700℃, the time will be fully automatically recorded), 23.5s±1.0s (1s ~ 999.9s) |

Exhaust system | Fully automatic exhaust, with a diameter of Ф100mm. |

Illumination system | High-grade explosion-proof lamp, fully automatic switch |

The moving mode of the burner | Motor + wire rod with a diameter of Ф16mm |

Test space | ≥ 0.5 cubic meters, with a black background |

Specifications and weight of the outer case | 1120*520*1250mm,60KG |

Zhipinhui After-Sales Policy:

*After-Sales Hotline: +864008166687

1. Our company has assembled a team of experienced field engineers and senior technicians to promptly respond

to any equipment issues and provide after-sales maintenance.

2. Within China, within one week of new product delivery, our after-sales technical staff will install the equipment and

provide after-sales training at the customer's location, using the contact information and address provided by the customer.

3. All complaints related to product quality will be responded to within one hour. Within 3-5 hours within the province,

and within 24-48 hours outside the province, we will arrive at the customer's site,

determine the appropriate action based on the complaint, and provide after-sales repairs. (Domestic)

4. For international travel, our company can also arrange for an after-sales engineer to visit you for installation and

commissioning. Please discuss any travel and catering issues in advance.

We also provide video installation guides for you to choose from, providing you with a comprehensive and multi-faceted solution.

5. Any material costs related to product quality during the warranty period will be borne by our company.

6. During the warranty period, we will provide free repairs due to improper use or environmental factors.

The materials and accessories used for repairs will be charged at cost only.