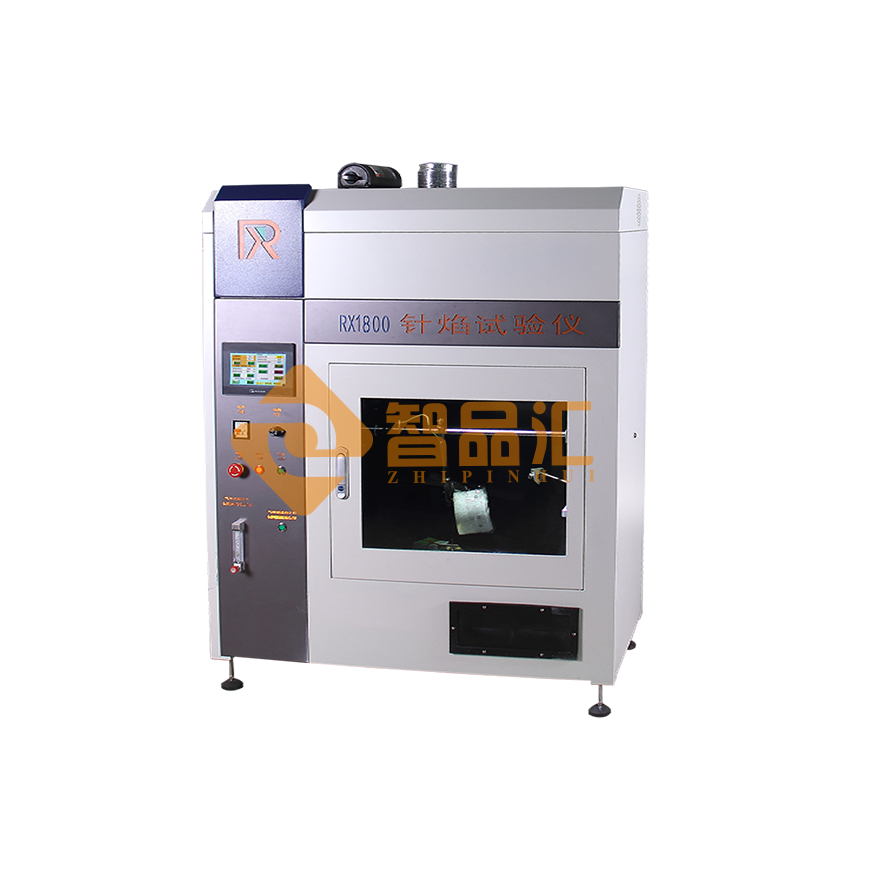

RX1800 Needle Flame Tester

The needle flame tester is a simulation test item specified in standards such as IEC 60695-2-2, GB 5169, GB 4706, and GB 7000.1-2015.

The needle flame tester is made of all stainless steel plate with a high-end spray coating outer box; Adopting the most advanced embedded computer control technology to achieve fully intelligent control, truly realizing networked and remote control; Taiwan Weilun 7-inch TFT true color LCD touch screen; Upgrade the user-friendly interface for customers and truly achieve international comparison results.

The needle flame tester uses a needle shaped burner with a specified size (Φ 0.9mm), supplied with specific gas (butane or propane), and timed at a 45 ° angle to ignite the test sample. The ignition hazard of small flames caused by fault conditions inside the equipment is evaluated based on whether the test sample and the ignition cushion layer are ignited, the holding time, and the combustion length.

The needle flame tester is suitable for research, production, and quality inspection departments of electrical and electronic equipment and their components, such as lighting, low-voltage electrical appliances, household appliances, machine tool appliances, motors, power tools, electronic instruments, electrical instruments, information technology equipment, electrical affairs equipment, electrical connectors, accessories, etc. It is also suitable for industries such as insulation materials, engineering plastics, or other solid combustible materials.

performance parameter :

control panel | Control interface: Chinese, Mitsubishi PLC+Weilun touch screen |

Compliant with standards | IEC 60695-2-2 、GB 4706.1、GB 7000.1-2015 and other standards |

Burner needle tube | Needle with an outer diameter not exceeding 0.9mm and a length of 35mm or more, with no air intake, measuring 0.5 ± 0.1mm |

Burner needle tube material | stainless steel |

Experimental angle | 90°、45°、20° |

flame height | 12mm ± 1mm, adjustable according to standard requirements, equipped with adjustable flame height gauge, made of 304 material |

standard fixture | Up and down+left and right+front and back |

Automatic positioning system | Use infrared sensing switch to automatically locate the position of the burner |

Temperature display range | 0-9999 ℃, resolution: 0.01 ℃ |

gas regulation | Equipped with gas flow and gas pressure regulation |

temperature measuring system | B+b thermocouple (Kai Zhuang K-type)+high resolution copper head (Φ 4mm ± 0.01mm, mass 0.58g ± 0.01g) |

Inside the test box | The illuminance meets the standard requirement of ≤ 20LX, making it easy to observe flames |

Laying material | Pine board (200 * 200 * 10mm), silk paper (1500 * 500mm) |

Gas source | 95% butane gas (reference gas), standard one bottle |

Gas source location | Outside the box |

Temperature testing standards | 100~700 ℃ (fully automatic recording time at 700 ℃), 23.5s ± 1.0s (1s ~999.9s) |

Exhaust System | Fully automatic exhaust, Ф100mm |

Illumination system | Advanced explosion-proof lamp, fully automatic switch |

Burner movement method | Motor+Ø 16mm wire rod |

试验空间 | ≥ 0.5m³ ,Background Black |

Specification and weight of outer box | 1120*520*1250mm,60KG |

RX1810 Hot Wire Tester

The hot wire tester is our company's all stainless steel plate with high-end spray coating outer box; Adopting imported Mitsubishi PLC microcomputer control to achieve fully intelligent control mode; Taiwan Weilun 7-inch TFT true color touch screen; Upgrade the user-friendly interface for customers and truly achieve international comparison results.

The hot wire tester is based on GB 4706.1, GB 7000.1, IEC60695-2-10 to IEC60695-2-13 "Hot wire/hot wire, basic test methods, hot wire test apparatus and general test procedures" and UL 746A IEC829, DIN695, VDE0471 and other standards stipulate the use of flameless ignition source program simulation test items.

The hot wire tester is suitable for research, production, and quality inspection departments of electrical and electronic products and their component parts such as lighting equipment, low-voltage appliances, household appliances, machine tool appliances, motors, power tools, electronic instruments, electrical instruments, information technology equipment, electrical affairs equipment, electrical connectors, and accessories. It is also suitable for industries such as insulation materials, engineering plastics, or other solid combustible materials.

Technical Parameter:

control mode | Adopting imported Mitsubishi PLC control, achieving fully intelligent control mode and stable system |

Display mode | Taiwan Weilun LCD display can upgrade the user-friendly interface for customers |

Glow wire | 4mm ± 0.04mm Ni/Cr(77/20) Specially designed standard circular, horizontal stationary |

thermocouple | Φ 1.0mm K-type, imported insulated high-temperature armored thermocouple, armored sleeve heat-resistant 1100 ℃ (better than standard 1050 ℃) |

Heating temperature of hot wire through electrification | 500 ℃~1000 ℃ (pre-set), temperature fluctuation<2 ℃ |

Test pressure for hot wire test of the sample | 0.95N±0.1 |

Maximum ironing depth | 7mm ± 0.5mm (adjustable, fully automatic positioning) |

Sample movement speed | 10mm /s ~ 25mm /s (Fully automatic) |

Test time | 30s±0.1s(1s ~ 999.9s Can be preset) |

Ignite the thickness of the cushion plate | 10mm thick white pine board covered with 12g/m2~30g/m2 standard silk paper, 200mm ± 5mm below the hot wire |

Experimental area volume | ≥ 0.5m3 background black background illumination ≤ 20Lx; |

External dimensions | Width 1120mm x Depth 520mm x Height 1020mm, Exhaust hole 100mm |

Power supply power | 1kVA 220V 50- |

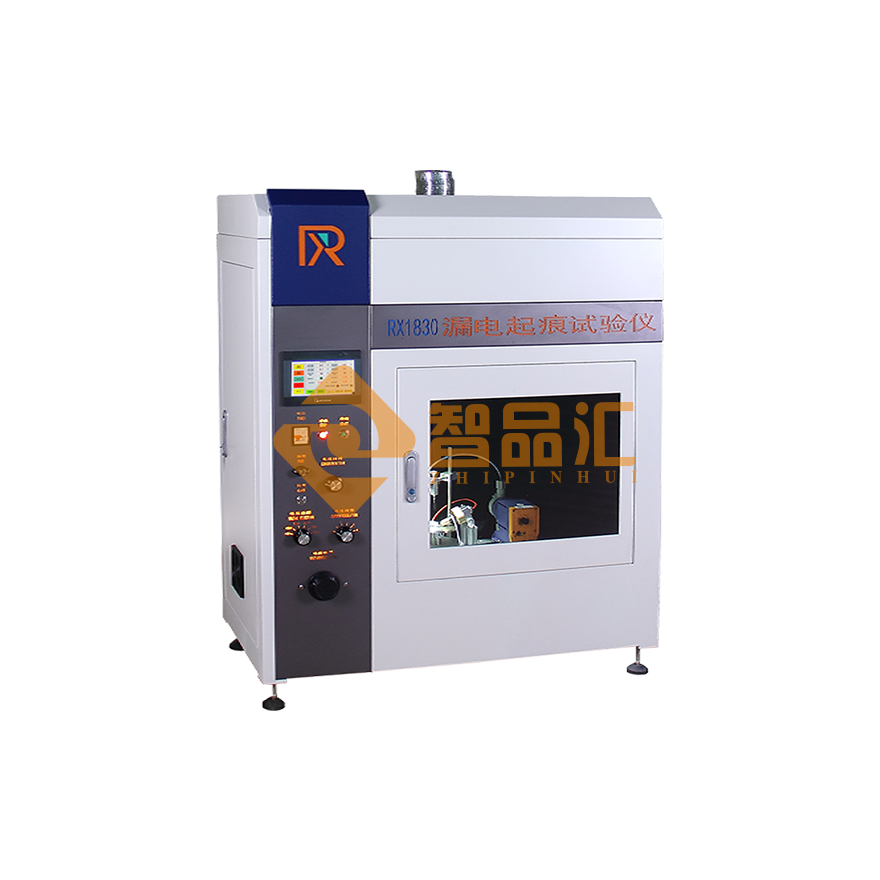

RX1830 leakage trace tester

The leakage trace tester is made of all stainless steel plate with a high-end spray coating outer box; Adopting the embedded computer control of Mitsubishi PLC to achieve fully intelligent control mode, truly realizing networked and remote control; There are 5.7 "(4:3), 6.4" (4:3), and 7.0 "(16:9) TFT true color LCD screens available for selection; Upgrade the user-friendly interface for customers and truly achieve international comparison results.

The leakage trace tester is based on GB 4706.1, GB 4207, GB/T6535, GB7000.1, IEC60112 "Determination method for resistance to electric trace index and comparative electric trace index of solid insulation materials" Simulation test items specified in standards such as UL 746A, ASTM D 3638-92, DIN 53480, etc.

The leakage tracing test (electric trace index test) is a test conducted on the surface of solid insulation materials. A certain voltage is applied between platinum electrodes of a specified size (2mm × 5mm), and a specified droplet volume of conductive liquid (0.1% NH 4 CL) is dropped at a fixed height (35mm) for 30 seconds to evaluate the leakage resistance performance of the solid insulation material surface under the combined action of electric field and humid or polluted medium. The comparison between the electric trace index (CT1) and the electric trace resistance index (PT1) is determined.

The leakage trace tester is suitable for research, production, and quality inspection departments of lighting equipment, low-voltage electrical appliances, household appliances, machine tool appliances, motors, power tools, electronic instruments, electrical instruments, and information technology equipment. It is also suitable for industries such as insulation materials, engineering plastics, electrical connectors, and accessories.

performance parameter :

control mode | Adopting advanced Mitsubishi PLC computer control to achieve fully intelligent control mode |

Display mode | True color LCD display, capable of upgrading the user-friendly interface for customers |

electrode size | ( 2mm ± 0.1mm )×( 5mm ± 0.1mm )×( 40mm ± 5mm ) ,30°±2° Length of foil gold section: 12mm (optional 5mm) |

electrode distance | 4.0mm ± 0.01mm ,included angle 60°±5°; |

Electrode pressure | 1.00N±0.001N; |

weighing system | Comes with weight sensor (automatically displays force value) |

Test solution resistance | Solution A: 0.1% NH4Cl, 3.95 ± 0.05 Ω m, B liquid 1.98 ± 0.05 Ω m; |

Droplet control | German imported micro pump |

Drop Volume | 20 drops of 0.380g to 0.480g& nbsp; 50 drops of 0.997g to 1.147g (adjustable); |

Droplet height | 35mm ± 5mm ( adjustable ); |

Droplet time | 30s ± 0.1s (better than standard) (digital display, adjustable preset), 50 drops time 24.5min ± 2min; |

Number of droplets | 1 ~ 9999( Digital display, can be pre-set); |

Test wind speed | 0.2m /s( New standards ); |

testing voltage | 100V ~600V(25V Scale division, adjustable ); |

Power supply voltage drop | 5% at 1.0A ± 0.1A; (10% better than the standard) |

Electrode material | Test electrode - platinum, electrode rod - purple copper or brass (optional pure silver) |

Exhaust System | One set of exhaust fan and one set of blowing fan (adjustable speed) |

Trace judgment | 0.50A ±10% , 2.00s±10% ;alarm sound |

External dimensions | Width 1120mm, depth 520mm, height 1350mm, exhaust aperture Φ 100mm; |

Test power supply | 220V 0.6kVA 50-60Hz 。 |

Zhipinhui After-Sales Policy:

*After-Sales Hotline: +864008166687

1. Our company has assembled a team of experienced field engineers and senior technicians to promptly respond

to any equipment issues and provide after-sales maintenance.

2. Within China, within one week of new product delivery, our after-sales technical staff will install the equipment and

provide after-sales training at the customer's location, using the contact information and address provided by the customer.

3. All complaints related to product quality will be responded to within one hour. Within 3-5 hours within the province,

and within 24-48 hours outside the province, we will arrive at the customer's site,

determine the appropriate action based on the complaint, and provide after-sales repairs. (Domestic)

4. For international travel, our company can also arrange for an after-sales engineer to visit you for installation and

commissioning. Please discuss any travel and catering issues in advance.

We also provide video installation guides for you to choose from, providing you with a comprehensive and multi-faceted solution.

5. Any material costs related to product quality during the warranty period will be borne by our company.

6. During the warranty period, we will provide free repairs due to improper use or environmental factors.

The materials and accessories used for repairs will be charged at cost only.